As a Nuts Bar Forming Machine Manufacturer, share with you. Food extruder is

a kind of extruder that uses screw extrusion to send materials into the

extruder. The screw of the flour extruder drives the material to form an axial

flow. At the same time, due to the mechanical friction between the screw and the

material, the material and the barrel, and the internal mechanical friction of

the material, the material is Strong extrusion, stirring, and shearing make the

material refined and homogenized. When the paste material is ejected from the

die hole of the Beijing extruder, the food extruder will expand, lose water, and

lose water under the action of a strong pressure difference. Cooling down

produces a loose, porous, and crispy puffed product. Fragrant crisps are loved

by humans and animals for their better palatability and flavor. And the price of

food puffing machines is low, if you are worried about the technical problems of

flour puffing machines. The quality of small puffing machines is not only the

twister of similar products, but also food The price of the extruder is low.

Snacks Bar Forming Machine

If you are worried about the technical problems of the extruder or flour

extruder, then you don't have to worry about it. Food puffing machine is a kind

of use of screw extrusion to send materials into the extruder. The screw of the

flour extruder screw drives the material to form an axial flow. The small

extruder is also due to the screw and the material.

Features of food puffing machinery

1. The extrusion screw is a living body variable pitch, special machine tool

processing, easy to replace, easy to maintain.

2. The gear transmission is helical gear, with large torque and low

noise;

3. Equipped with three inverters, the operation is more stable.

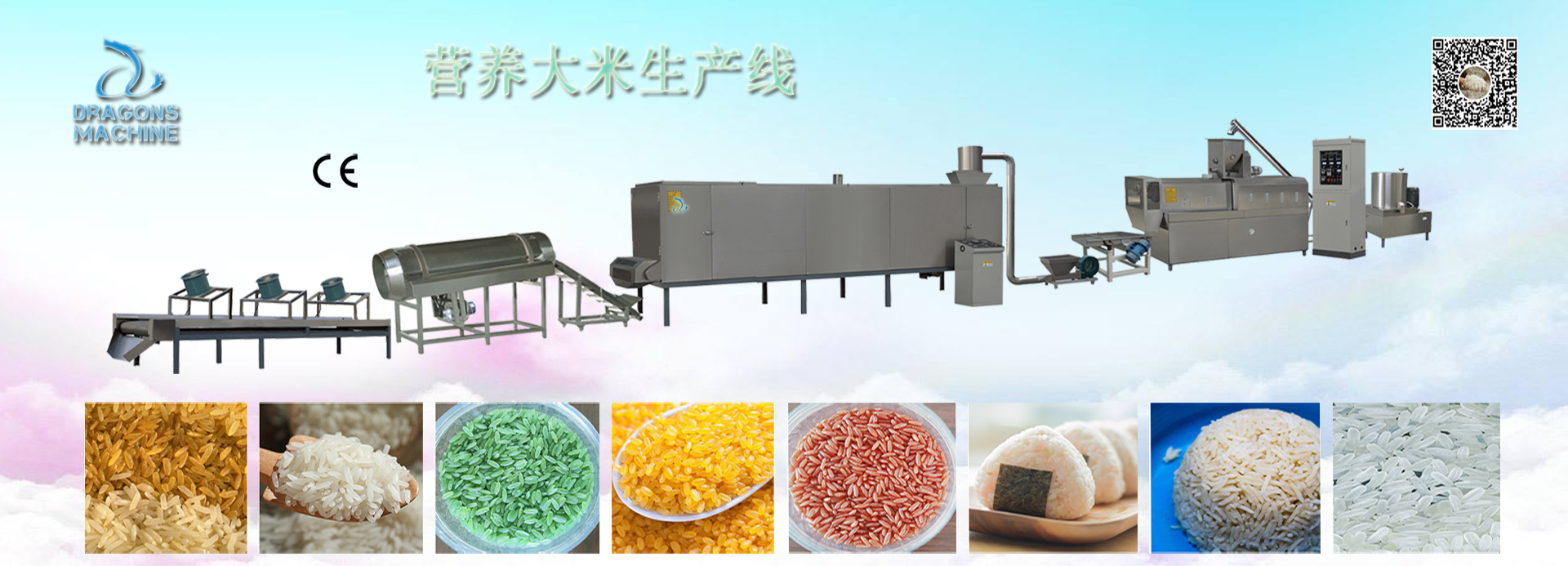

4. A wide range of applicable raw materials, rice, corn, grains and other

powdery materials can be used.

Instructions

1. After the food puffing machine is installed, check for looseness, and then

run the machine empty for 1-2 minutes. After confirming that there is no fault,

it can be added.

2. First, remove the head ring, remove 3-5 kg of the prepared powder into

the hopper for repeated extrusion, usually 3-5 minutes, when the temperature

reaches 6-70 degrees, you can install the die piece, master The cutting speed

can be slower when raw, and faster when it is overcooked. After normal, the

cutting speed can be uniform. The products can be cut according to the length of

the package.

3. During the operation, it is best to use a hardwood rod larger than the

feeding port to assist the cutting. It is strictly forbidden to push the

material with hands and metal objects to avoid hurting hands or damaging the

machine parts.

4. When the machine is stopped, add a little water to the discharge port

first to prevent the head ring and the working cylinder from sticking and not

easy to disassemble. When the machine is stopped, remove the head ring, the

straight discharge pipe, and the inlet and outlet wire cylinders in order and

cannot be changed. Remember to remember clearly when disassembling, change the

butter when the bearing is working.

Our company also has Snacks Bar Forming Machine on sale, welcome to contact

us.

中文

中文  English

English  Español

Español  Pусский

Pусский  عربى

عربى  日本語

日本語