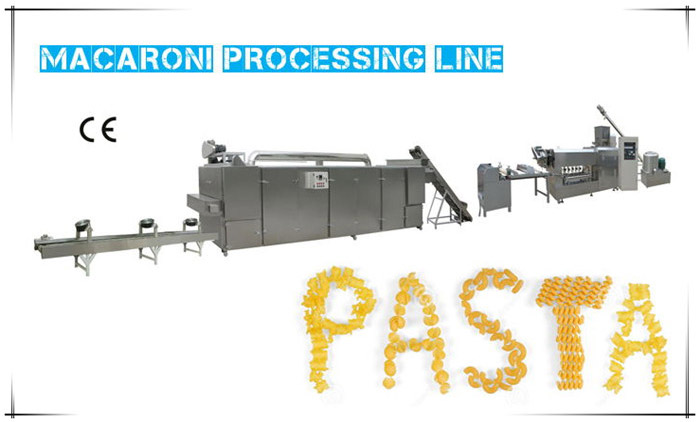

Macaroni Processing Line's repair is based on the wear and

tear of certain parts found during equipment maintenance, and is determined by

the equipment technicians. There is a planned replacement of certain parts to

ensure that the equipment can work properly. Equipment maintenance work can be

divided into scheduled normal maintenance and maintenance of sudden

accidents.

Macaroni Processing Line

1. Normal maintenance will be arranged by the production

survey meeting, giving time for equipment maintenance. Normally, repair work is

performed simultaneously with regular maintenance of the equipment. Maintenance

work items of the extruder: ① Replace worn gears, pulleys, rolling bearings and

V-belts; ② Grind and trim the scratches and burrs on the working surface of the

barrel and screw to achieve smooth, non-sticky materials; ③ Check the heating

resistance Replace the damaged cast aluminum heating jacket; ④ If the gap

between the screw and the barrel device is too far apart, the equipment the technician decides to repair the screw and barrel by repairing the welding or

replacing the screw; ⑤ The bearing glands are re-installed Replace the

gasket.

2. Sudden accident maintenance This sudden accident maintenance is an

unplanned emergency. In the normal operation of the extruder, due to metal

foreign matter falling into the barrel, or because the barrel temperature is low

and the temperature instrument fails, plasticizing the material is not good, and

the screw rotation torque suddenly increases, causing the screw, gear or The

working load of the thrust bearing is severely overloaded and damaged. Another

possibility is that the motor is overloaded and burned for a long time. In order

to ensure the completion of the monthly production plan, for such sudden

equipment accidents, we must pay close attention to time, day and night, and

repair the damaged parts. Preparations before maintenance ① Consult the

equipment drawings to understand the parts, accuracy requirements and working

conditions of the repair parts; ② Know the quality standards of the repair parts

and determine the repair plan; ③ Check the specifications and accuracy of the

replacement parts according to the part drawings Quality; ④ Prepare testing

instruments and disassembly and assembly tools.

As a Macaroni Processing Line Manufacturer, I would like to

share with you the four reasons for the noise of the extruder screw barrel.

During the process of extrusion processing, the screw of the extruder will

make a sound when it rubs against the inner wall of the barrel. The reason for

this friction phenomenon is the following four reasons:

1. The assembly gap between the extruder screw and its supporting drive shaft

is too large, and the centerline of the two shafts is not concentric during

rotation and the error is too large.

2. The extruder screw is bent and deformed, and the straightness of the axis centerline is greatly different.

3. The perpendicularity between the end face of the extruder barrel and the base flange of the machine base and the centerline of the barrel cannot be guaranteed, and the error is large.

4. The extruder screw is assembled in the barrel of the extruder, and the error of the concentricity of the two parts is large.

Our company also has Macaroni Machine on sale, welcome to

consult.

中文

中文  English

English  Español

Español  Pусский

Pусский  عربى

عربى  日本語

日本語